Enumerate and Explain Different Types of Lathe Machines

Gap bed lathe is used to machine large diameter work piece ie. 12 Types of Lathe Machines and Their Uses 1.

Lathe Machine The Ultimate Guide For Beginners

In Belt driven lathe Power from the motor is transmitted to the spindle by belt drive In Geared head lathe power from the motor is transmitted to the spindle by the gear drive.

. Different types of chucks. The direction of the movement of the cutting tool is actually controlled by the operator. Furnished with a speed-cone and back gears that make a varied range of spindle speeds.

Lathe Diagram How it Works. Each of these lathes has specific applications and distinctive characteristics. Having step-cone pulley drive and the back-gears to provide various speeds to the work.

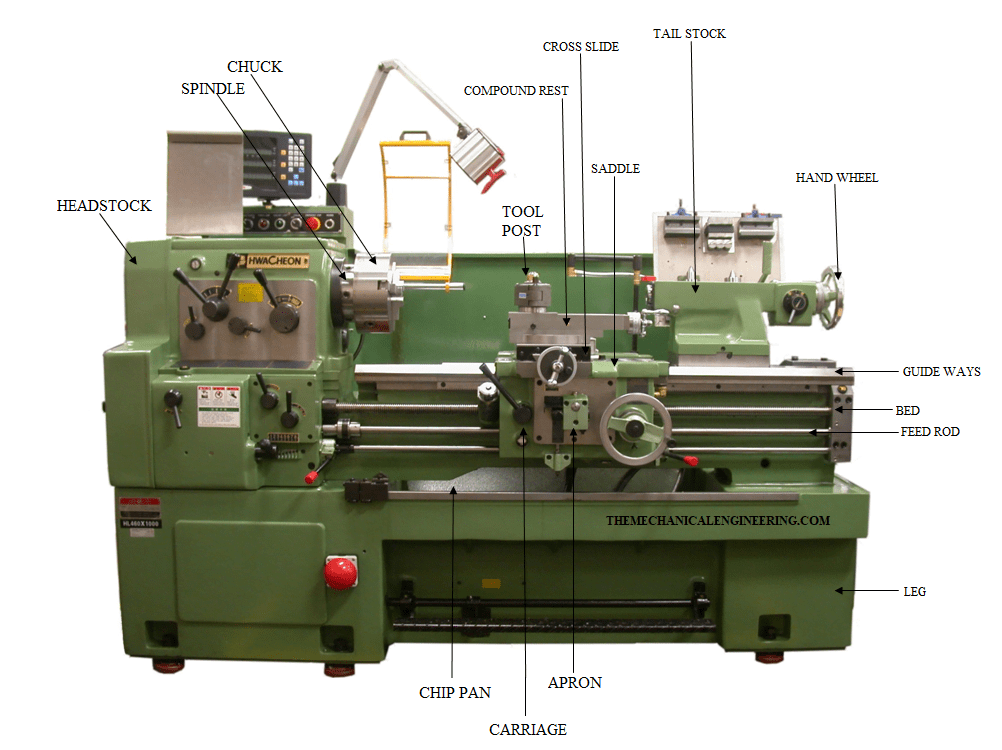

Parts of Lathe Machine Diagram. Vertical Turret Lathe VTL 10. Turning is the most simple and popular type of lathe machine operation.

Thread cutting on lathe Machine. It is a production machine that is used for the production of products on a large scale. There are three general types of lathe machines which are engine lathes turret lathes and special purpose lathes.

This is known that the power is received from the overhead line shaft is known as the belt drive. Motor Drive Lathe 3. Lathe Machine Parts Names.

Usually grooves are cut on a cylindrical surface in narrow shape by means of grooving tool. This kind of machine tool is usually used in the on-site repair workshop which can adapt to a variety of. Now lets see the working principle of it in a detailed way.

These are probably the most popular among the. Types of Lathe Machine Operations. This operation is also denoted as necking.

Thread Cutting on Lathe -Lathe Machine Operations. Types of lathe machines. It has no carriage or feed box lead screw.

The engine lathe is the most important tool in the Lathe family and by far the. The basic function of the Lathe machine is to remove the material from the surface of the workpiece by the usage of cutting tools providing the necessary amount of feed and this can be done by placing the workpiece in the chuck which. This includes speed lathe engine lathe tool-room lathe special-purpose lathe CNC lathe etc.

The cutting edge of grooving tool is kept narrow. There are six major types of turning operations. In this type the power is received by individual motors this is integral with the lathe machine is called a motor drive.

Tool Room Lathe 6. Lathe Machines are used in metalworking woodturning metal spinning thermal spraying glass working and parts reclamation. Parts of lathe machine with diagram.

By using this operation you can either remove the material from the outside or inside of the workpiece. Parts of the Lathe Machine and their functions. Engine Lathe or Center Lathe Machine.

Four Jaw Chuck-Three Jaw Universal Chuck-Air or Hydraulic operated Chuck-Magnetic Chuck-Collet Chuck-Combination Chuck-5. T-shape lathe are used to machine rotors used in jet engines and gas turbines. Wheel lathe is used for machining of journals and rail rods.

The speed of the lathe machine is 1200 to 3600 rpm. Lathes can be roughly divided into three types engine lathes turret lathes and special lathes. Turret Lathes and Capstan Lathes 9.

Hollow Spindle Lathe 8. These are the various types of Lathe machines. Working Principle of Lathe Machine The function of a lathe is to remove metal from a piece of work to give it a desired shape and size.

This type of drive calls for the use of a countershaft which carries a similar cone pulley to that provided on the lathe spindle. Following are the Lathe machine operations done either by holding the workpiece between centres or by a chuck. The various other operations that you can perform with the help of Lathe.

Gap Bed Lathes 5. The engine lathe depending upon the design of the headstock for receiving power may be classified as belt-driven lathe motor-driven lathe and geared head lathe. You can perform this operation on wood metals and plastics.

Wood Turning Lathe 2. The lathe machine operations are classified into three main categories and are as follows. A specific motor integrated with the device supplies its power to the lathe.

According to the type of drive the lathes can be grouped as. The basic engine lathe is used for most lathes with the smaller bench or portable machines or larger vertical tables standing on the floor. It is made of the single-piece casting of Semi-steel.

Gearhead Lathe Belt Drive Lathe. Belt Drive Lathe 2. A lathe machine is a machine tool which is used to remove metals from a workpiece to give a desired shape and size.

Special Purpose Lathes 11. Up to 15 to 2 meters and 6-8 meters in length. It is the base of the lathe machine.

Power supplied through overhead line shaft. It is similar to. Belt driven lathe machine.

There are different types of lathe machines that have become part of different manufacturing industries. The turret lathe is another metalworking machine but this is built specifically for mass production. Lathe machine are of different types according the types of work performed.

Lathe machine run by a motor. It consists of bed tailstock headstock tool post installed on the adjustable side. It is also used for turning the threads on locomotive wheels.

The eight primary parts that make up a lathe machine include. Plain or Straight Turning. Working Principle of Lathe Machine.

The bed the base the headstock for rotating the spindle the tailstock for securing your tool bit the carriage your guide the cross slide for moving your tool bit back and forth the saddle which supports cross slide movements the apron the gears and clutches and the legs for elevating your lathe. The way this lathe works is that multiple shaping tools are mounted on a saddle. In terms of power supply it is three types.

Centre Lathe or Engine Lathe 4. 1 Speed Lathe Machine. Head Stock is situated at the left side of the lathe bed and it is the house of the driving mechanism and electrical mechanism of a Lathe.

Turning is the mother of all the other lathe machine operations. This type of lathe eliminates many variables in the production process that could hinder the final product making mass production a possibility.

Lathe Machine Definition Parts Types Operation Specification Advantages Application Notes Pdf

What Is Lathe Machine Types Of Lathe Machine Their Uses Complete Guide Engineering Learn

Do You Know What Are The Different Types Of Lathe Machine Machine Future Machinery Future Machine Tool Industry All In Here

Comments

Post a Comment